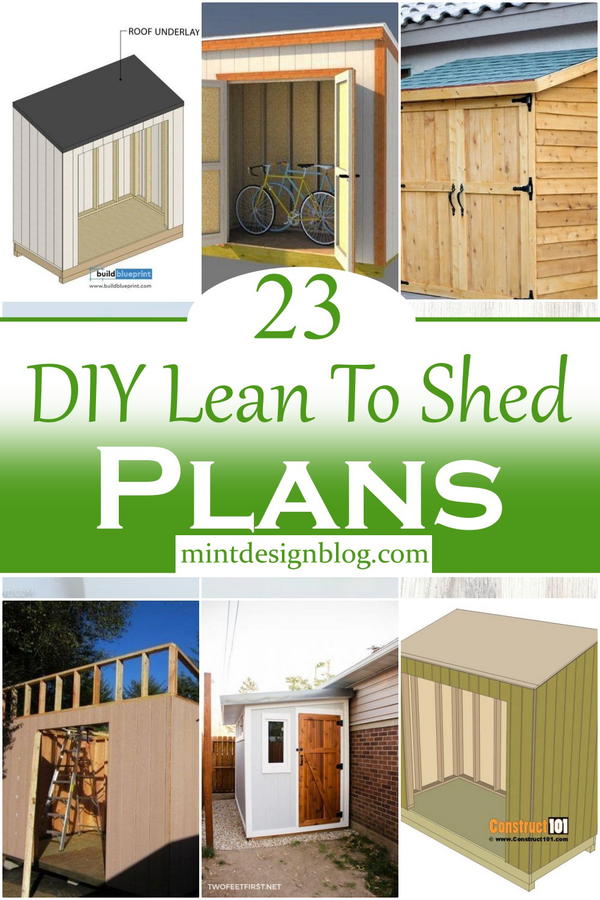

Lean-To Shed Build: Affordable Plans for Backyard Storage Solutions

Tired of clutter overflowing your garage and taking over your precious backyard space? A lean-to shed offers a simple, cost-effective solution for maximizing storage without breaking the bank. This guide provides detailed plans and considerations for building your own affordable lean-to shed, transforming your outdoor area into a well-organized haven.

Planning Your Lean-To Shed: Size and Location

Before you even pick up a hammer, careful planning is crucial. Determine the ideal size for your lean-to shed based on your storage needs. Consider the items you’ll be storing â€" lawn equipment, gardening supplies, bicycles, or tools? Measure these items to get an accurate estimate of the necessary internal space. Don't forget to account for comfortable access and maneuvering within the shed. Next, carefully select the location. Choose a level area with sufficient sunlight for natural ventilation and easy access from your house or yard. Check local building codes and regulations regarding shed placement, setbacks, and height restrictions. Ensure the chosen spot has suitable drainage to prevent water accumulation around the foundation.

Gathering Materials and Tools: Your Lean-To Shed Shopping List

Building a lean-to shed requires a specific set of materials. A detailed list is essential for efficient shopping. You'll need pressure-treated lumber for the foundation, framing, and roofing. Choose the right dimensions for your chosen shed size. Consider purchasing additional lumber for extra support beams or bracing if needed. Select roofing materials that are durable, weather-resistant, and within your budget â€" options include asphalt shingles, metal roofing, or even recycled plastic roofing. Don't overlook essential hardware like screws, nails, anchors, and flashing. Remember to account for any necessary concrete for your foundation (if not opting for a gravel base). Finally, assemble your toolbox. You'll require essential tools such as a measuring tape, level, saw (circular saw or hand saw), drill, hammer, shovel, and safety glasses.

Step-by-Step Construction: Building Your Affordable Lean-To

Foundation and Framing:

Begin by preparing a level foundation. For a budget-friendly option, consider using gravel or compacted earth for smaller sheds. For larger structures or areas prone to flooding, a concrete slab provides a more durable base. Once the foundation is complete, erect the frame using pressure-treated lumber. Precise measurements and careful cuts are crucial here. Use your level frequently to ensure the frame remains plumb and square. Consider installing additional support beams or braces for added strength and stability, especially if your shed will house heavier items.

Roofing and Siding:

After completing the frame, install the roofing. Begin by attaching the roof sheathing to the rafters, creating a solid base for your chosen roofing material. Carefully install your chosen roofing material according to the manufacturer's instructions, ensuring proper overlap and sealing to prevent leaks. Next, add the siding. Common and affordable siding options include plywood or pre-fabricated panels. Choose a siding material that complements your home's exterior and weather conditions. Secure the siding with nails or screws, paying attention to sealing any gaps to prevent moisture damage.

Finishing Touches and Safety:

Once the main structure is complete, add finishing touches such as a door and any necessary windows. Consider installing simple shelving or hanging hooks inside for better organization. Remember to address safety concerns. Ensure all sharp edges and corners are appropriately secured or covered to prevent injuries. Regularly inspect the structure for any signs of wear and tear, particularly after harsh weather conditions, and make necessary repairs promptly.

Tips for Keeping Costs Down

Building a lean-to shed affordably requires careful planning and resourcefulness. Consider reclaiming materials from demolition projects for the framing, or explore cost-effective options like recycled plastic lumber. Look for sales and discounts on lumber and roofing materials. Don't hesitate to enlist help from friends or family to reduce labor costs. Prioritize essential features and postpone less crucial elements until a later date if your budget is tight. By planning ahead and utilizing resourceful strategies, you can build a functional and attractive lean-to shed that suits your needs without depleting your savings.